Renewable Design for Self Drilling Window Screws - Truss Head Phillips Drive White Zinc Plated Self Drilling Screw – Xinruifeng

Renewable Design for Self Drilling Window Screws - Truss Head Phillips Drive White Zinc Plated Self Drilling Screw – Xinruifeng Detail:

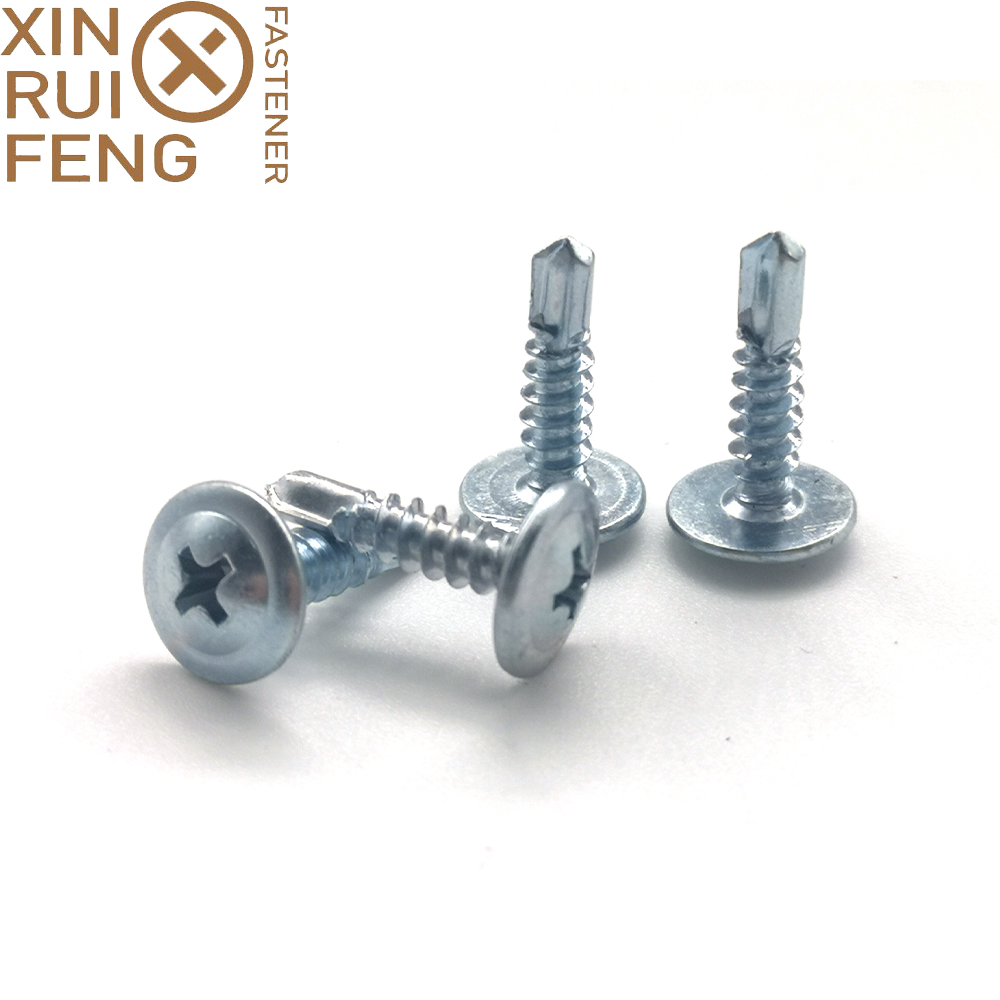

| Head Type | Truss Head |

| Drive type | Phillip Drive |

| Diameter | M3.5(#6) M3.9(#7) M4.2(#8) M4.8(#10) M5.5(#12) |

| Length | From 13mm to 100mm |

| Material | C1022A |

| Finish | Yellow/White Zinc Plated; Nikel Plated; Ruspert |

| Standard | DIN/ ISO/ GB |

1: The end of the screw is drill point. No auxiliary machining is required, drilling, tapping, and locking can be done directly on the setting material and base material, totally saving construction time.

2: Compared with common screws, it has high tensile strength and maintenance force, and will not loosen even after a long period of time, making it safe to use.

3: This round head with truss, for small screws that disperse the weight of the load.

4: We have our own heat treatment produce line. Heat-treated self drilling screws with high strength drilling capability. We control the temperature of heat treatment in strict accordance with DIN standards to achieve the highest quality.

Tianjin Xinruifeng Technology Co., Ltd. has been in the fastener industry for nearly 20 years and we can customize all kinds of products per your requirements. We have an established management system and quality control procedure. Excellent quality, competitive price, and timely delivery are the pillars of the company’s foundation. Win-win and long-term cooperation is our final goals when dealing with different clients.

Self drilling screw series is one of the most important categories in the entire fastener product line. Especially in the construction, building, housing and other places, the best one of economic fastener in terms of workability, cost and reliability is the self drilling screw.

Self-Drilling Screws for Metal

Self-drilling screws can be used to fasten sheets of metal to another material, or even to join metal to metal. Not only does this set them apart in comparison to other common screw types, but it also makes them highly useful across a broad spectrum of industries and applications. To name just a few examples, ideal uses could include working with metal roofing, HVAC and ductwork, and steel frames.

Self-Drilling Screws for Wood

While purpose-manufactured wood screws are typically the first choice for tasks involving wood, self-drilling screws may also prove useful in certain woodworking scenarios. For instance, self-drilling screws for wood may be used in the construction, repair, or maintenance of sheds and outbuildings, as well as general construction tasks.

Self-Drilling Screws for Plastic

Self-drilling screws can also be used with plastic in certain applications and environments. One instance for using self-drilling screws with plastic could be to fasten sheets or components together when working with ductwork and plastic piping.

Product detail pictures:

Related Product Guide:

Our mission is to become an innovative supplier of high-tech digital and communication devices by providing value added design, world-class manufacturing, and service capabilities for Renewable Design for Self Drilling Window Screws - Truss Head Phillips Drive White Zinc Plated Self Drilling Screw – Xinruifeng, The product will supply to all over the world, such as: Toronto, Cyprus, Philadelphia, Our staffs are rich in experience and trained strictly, with qualified knowledge, with energy and always respect their customers as the No. 1, and promise to do their best to deliver the effective and individual service for customers. The Company pays attention to maintaining and developing the long-term cooperation relationship with the customers. We promise, as your ideal partner, we'll develop a bright future and enjoy the satisfying fruit together with you, with persisting zeal, endless energy and forward spirit.

The supplier abide the theory of "quality the basic, trust the first and management the advanced" so that they can ensure a reliable product quality and stable customers.