8 Year Exporter Screw Fitting Machine - Torx Drive Countersunk Chipboard Screw Zinc Plated with Saw Thread – Xinruifeng

8 Year Exporter Screw Fitting Machine - Torx Drive Countersunk Chipboard Screw Zinc Plated with Saw Thread – Xinruifeng Detail:

Chipboard Screw:

1. Heat treatment: It is a method of heating steel to different temperatures and then using different cooling methods to achieve different purposes of changing the properties of steel. The commonly used heat treatments are: quenching, annealing, and tempering. What kind of effects will these three methods produce?

2. Quenching: A heat treatment method in which the steel is heated to above 942 degrees Celsius to make the steel crystals in austenitic state, and then immersed in cold water or cooling oil to quench to make the steel crystals in a martensitic state. This method can increase the strength and hardness of the steel. There is a very big difference in the strength and hardness of the steel with the same label after quenching and without quenching.

3. Annealing: A heat treatment method in which the steel is also heated to an austenitic state and then naturally cooled in air. This method can reduce the strength and hardness of the steel, improve its flexibility, and facilitate processing. Generally, steel will go through this step before processing.

4. Tempering: Whether it is quenched, annealed or press-formed, steel will generate internal stress, and the imbalance of internal stress will affect the structure and mechanical properties of the steel from the inside, so a tempering process is required. The material is kept warm continuously at a temperature of more than 700 degrees, its internal stress is changed and then cooled naturally.

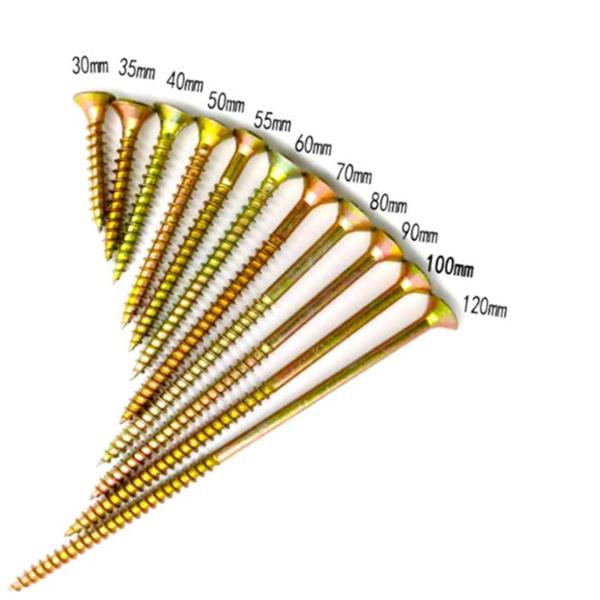

1. The chipboard screws are mainly used for woodworking such as furniture assembly or flooring, etc. This is why we also call it screws for particle board or screws MDF. We offer a wide range of chipboard screws whose length is from 12mm to 200mm. Generally, the small chipboard screws are perfect for fastening hinges on chipboard cabinets while larger screws are used to join the bigger pieces of a cabinet, etc.

2. Basically, there are two kinds of chipboard screws: white zinc plated or yellow zinc plated. The zinc plating isn’t only a layer of protection to resist corrosion, but also matches the aesthetic of the project. Besides our chipboard screw is characterized by a deeper Pozi recess that helps to avoid cam-out and also extends the life of the bit used to drive the screw.

Product detail pictures:

Related Product Guide:

To be a result of ours specialty and repair consciousness, our corporation has won an excellent reputation amongst customers all around the entire world for 8 Year Exporter Screw Fitting Machine - Torx Drive Countersunk Chipboard Screw Zinc Plated with Saw Thread – Xinruifeng, The product will supply to all over the world, such as: Uruguay, UK, Lithuania, We can give our clients absolute advantages in product quality and cost control, and we have full range of molds from up to one hundred of factories. As product updating fast, we succeed in developing many high quality products for our clients and get high reputation.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.